Previously most of the interest around the surf park sector has centred on which technology can deliver the best waves and the highest surfer capacity. That’s understandable; surfers want to ride the best waves for their level and catch as many of them as possible.

In a surf park industry first, a detailed study into the energy efficiency of Wavegarden’s electromechanical system vs. pneumatic technology has been released to the public. The study concludes that the Wavegarden system requires approximately 10 times less energy than a pneumatic system on a like-for-like basis.

Yet the focus on the pure “surf experience” for the customer has meant that detailed, scientific analysis of the energy consumption required to make the waves has been lacking. Given that this has one of the biggest impacts on both environmental sustainability and operational costs, this needs addressing.

Very few, if any, surf park companies apart from Wavegarden provide real information about the energy consumption of their technologies. This is particularly the case with pneumatic systems. Most of the published data rely on theoretical models, and not actual data from full-scale operational parks. This lack of transparency has made comparing the energy efficiency of the various technologies difficult.

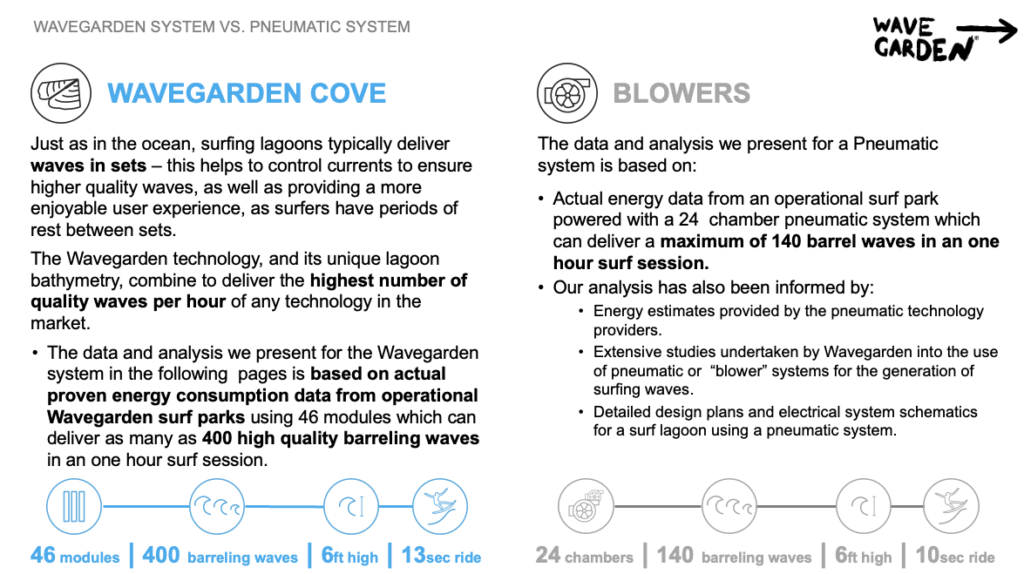

With more than 15 years of experience of designing and delivering commercially successful surfing lagoons, the data and analysis presented in the study are based on actual energy data from operational Wavegarden surf parks. This findings were then compared with actual energy use data for an operational pneumatic system surf park.

While the report was commissioned by Wavegarden, the study’s detailed and rigorous scientific methodology means it provides a realistic ‘‘apples with apples” comparison. To provide a more transparent assessment, the study compares different wave types, sizes and lengths and ensures that actual single waves are considered, rather than the number of ‘surf rides’ that a single wave can generate in secondary areas of the lagoon.

The analysis also takes into consideration the very important `stand-by’ energy consumption of the technologies required between wave generating periods. That ensures the entire energy demand of a full one-hour surf session with the same number and type of waves can be compared correctly.

The results of the comparison are clear – the Wavegarden system requires approximately 10 times less energy than a pneumatic system on a like-for-like basis. Wavegarden’s technology consumes only 250-450 kilowatts per hour (kWh), or less energy than a single chair lift at a ski resort. Peak demand and transformer requirements are also significantly lower than for an equivalent pneumatic system.

The efficiency gains come mainly from how the waves are created. The Wavegarden system uses electric motors to move mechanical paddles. There is minimum energy loss during the transmission of forces from the machinery to the water.

Additionally, hydrodynamic forces (as the paddle moves back into position) are used to regenerate energy during the process. Finally, the energy consumption in the period between wave sets, known as standby consumption, is extremely low.

The pneumatic system uses a motor to power a blower, which then moves air through a chamber to create a wave. There is more significant energy loss due to the additional component of air; a compressible gas. Furthermore, the hot pressurised air inside the chamber, representing energy, is lost into the atmosphere after creating the wave. The standby consumption is also high as the blowers must continue to push air into the chambers to maintain pressure even when waves aren’t being produced.

The resulting energy savings in the Wavegarden system not only have a positive environmental effect but make a huge difference in operational costs. In a busy surf park delivering 1 to 2 million waves per year, savings of between $1.3m to $2.7m per year (based on an average electricity price of $0.15 per kWh) can be made.

Yet there is much more work to be done. Wavegarden facilities in Brazil, Bristol, Melbourne, Switzerland, and Spain are powered by renewable energy sources. However, the ultimate goal is to offer completely carbon-neutral surf parks through the use of photovoltaic (PV) panels.

The development of a new Energy Management System, combined with PV panels to be located in the park itself, is currently underway by Wavegarden. Analysis indicates this is currently economically unfeasible for standard pneumatic systems given the high energy demands and large area of land that would be required.

As the surf park sector continues to grow, the ultimate aim is to provide a tremendous asset for any community, delivering positive economic and social benefits while exhibiting the utmost respect for nature and the local environment. High quality artificial waves can, and should, be made using the most energy efficient approach possible. Electric wave making systems, like that developed by Wavegarden, must be the future.